- Видео

- Наука и технологии

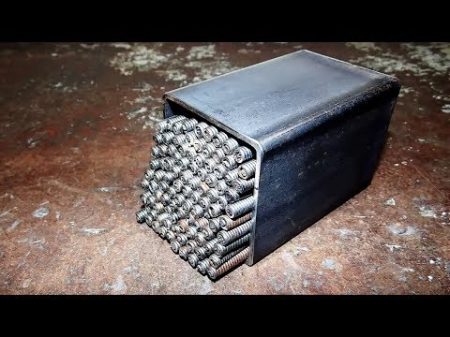

- Damascus of screws making a blade

Damascus of screws making a blade

The process of forging a blade from self-tapping screws, in two ways.

my website: sites.google.com/site/damaskshevchenko/

Frequently Asked Questions: The billet is soaked in kerosene. This is necessary for good welding (forging) steel. I sprinkle flux (90% borax + 5% quartz sand + 5% charcoal powder) this is necessary for forging (forge) welding. The flux is alloyed with scale — the formed substance is sufficiently fluid and is easily displaced by deformation. In addition, the flux protects against oxygen and charcoal, carburizes the surface layer of metal — which lowers the welding temperature (if in brief). The first welding is done on a tree, since the wood is a heat insulator, and not so selects temperature as an iron anvil. In addition — burning, the tree burns oxygen, protecting the workpiece and pouring the flux work. This is important for welding workpieces with small parts (cable, chain). I do not answer the question of cost — write to mail: sites.google.com/site/damaskshevchenko/-19

Be tolerant: For mate, insults and politics — ban.

www.facebook.com/groups/1961092850801182/

Channel Support www.patreon.com/shurap

# DamascusSteel

my website: sites.google.com/site/damaskshevchenko/

Frequently Asked Questions: The billet is soaked in kerosene. This is necessary for good welding (forging) steel. I sprinkle flux (90% borax + 5% quartz sand + 5% charcoal powder) this is necessary for forging (forge) welding. The flux is alloyed with scale — the formed substance is sufficiently fluid and is easily displaced by deformation. In addition, the flux protects against oxygen and charcoal, carburizes the surface layer of metal — which lowers the welding temperature (if in brief). The first welding is done on a tree, since the wood is a heat insulator, and not so selects temperature as an iron anvil. In addition — burning, the tree burns oxygen, protecting the workpiece and pouring the flux work. This is important for welding workpieces with small parts (cable, chain). I do not answer the question of cost — write to mail: sites.google.com/site/damaskshevchenko/-19

Be tolerant: For mate, insults and politics — ban.

www.facebook.com/groups/1961092850801182/

Channel Support www.patreon.com/shurap

# DamascusSteel

развернуть свернуть

17:43

- Комментарии

RSS

Нет комментариев. Ваш будет первым!

Войдите или зарегистрируйтесь чтобы добавлять комментарии